All decision-making and forming of all strategies are aligned to “Quality Operating System“ ensuring that market share, competitiveness, and profitability is achieved by Continuous Improvement.

Our “Zero Defect” target manufacturing policy is achieved by continuous training of our workforce to promote their ownership. Customer satisfaction is achieved by offering the desired quality and services cheaper than our competitors.

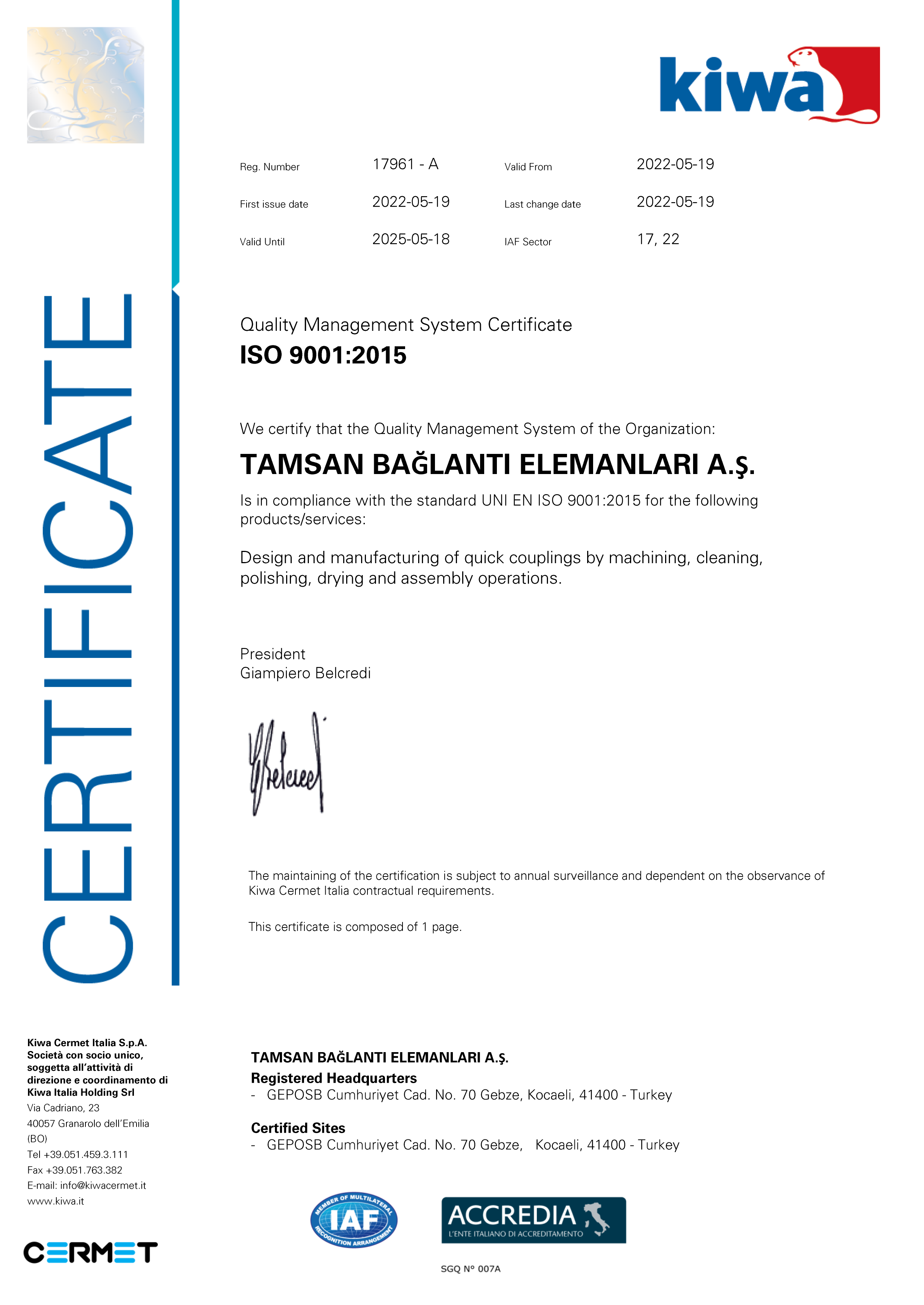

Our Company having been awarded ISO 9001 certification is now going through the final stages of the IATF 16949 implementation process and targeting to serve its customers as a IATF 16949 certified establishment before the end of 2017.

In addition to our in-process verification measuring processes, we have a well-established Laboratory facility with up-to-date testing equipment for profile projection, hardness testing, surface measurement, dimensional accuracy, and high-pressure hydraulic testing equipment enabling us to verify incoming materials as well as our own produced products.

Quality Policy

-

Fulfilling the requirements of Quality Management System Standards,

-

Focusing on customer satisfaction by providing top-quality products meeting customers' requirements,

-

Continuous developments in all related fields with our solution partners and improving quality/ competitiveness internationally,

-

Continuous employee training and employer contribution to work,

-

All projects to comply with the benefits of the environment and co-workers,

-

Complying customer's conditions and provisions, are committed by our company.